What are neoprene cables and when to use them

Neoprene cable, also referred to as polychloroprene cable, are robust electrical cables made of synthetic rubber that are suitable for use outdoors and in challenging environments. These cables are commonly used as fixed or mobile cables in areas exposed to mechanical stresses, oils, chemical corrosion and weathering, and can even fulfill the needs of many industrial applications.

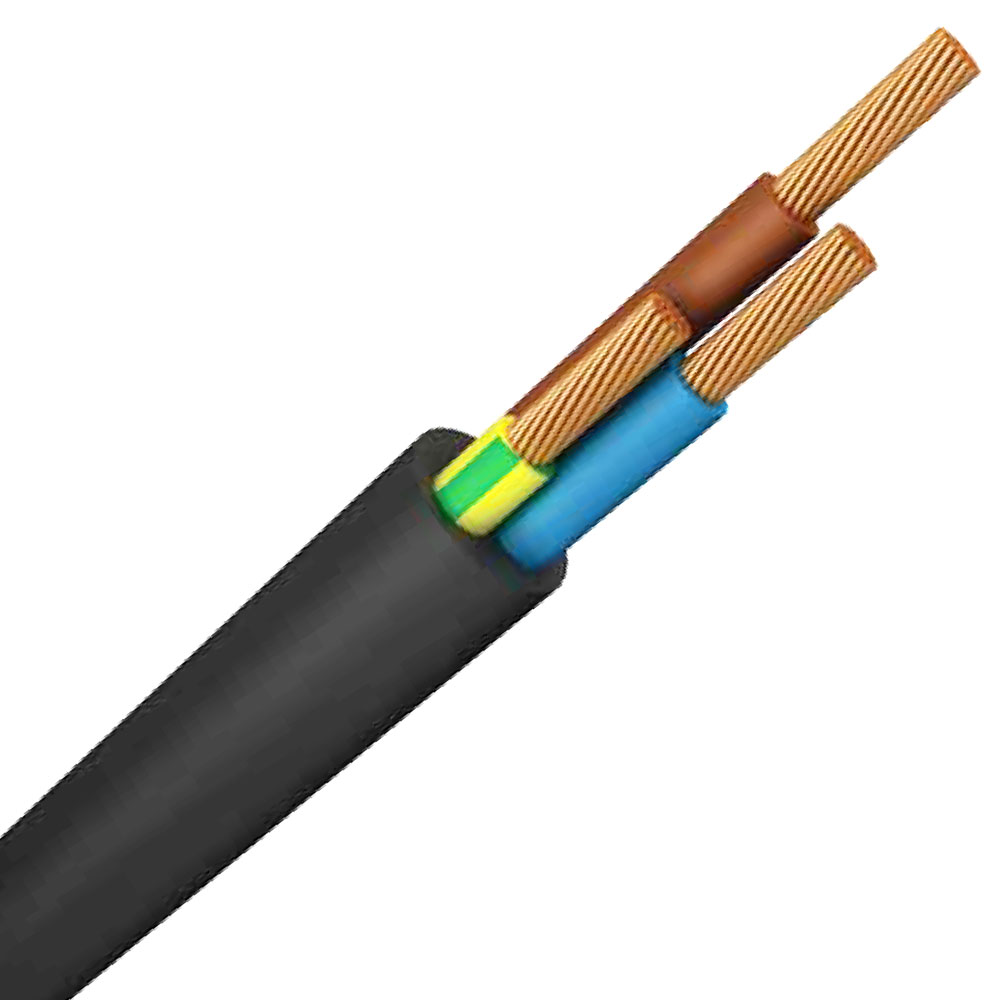

These cables comprise of a conductor, usually copper, insulated with ethylene propylene rubber (EPR), that is then sheathed with neoprene rubber. Their material and construction make them suitable for medium mechanical stress in dry, damp, and wet areas. You can find these cables in many outdoor electrical installations and in agricultural and industrial settings.

Neoprene cables are also known for their flexibility, which allows for easy installation and adaptability to various environments. Furthermore, the EPR insulation provides an enhanced resistance to factors such as heat, oxidation, and UV radiation.

What is neoprene rubber

Neoprene, also known as polychloroprene, is a synthetic rubber produced by the polymerization of chloroprene. It exhibits good chemical stability and maintains flexibility over a wide temperature range. Neoprene is especially valued for its water, oil, and weather-resistant properties, making it an excellent choice sheathing cables that require durability and resistance to environmental factors.

What is ethylene propylene rubber (EPR)

Ethylene propylene rubber (EPR), commonly referred to as EPDM in some contexts, is a type of synthetic elastomer characterized by its superior resistance to heat, oxidation, and ozone. Produced from the copolymerization of ethylene and propylene, EPR boasts of excellent electrical insulating properties. Its inherent flexibility, even at high temperatures, combined with its resistance to moisture and various chemicals, makes EPR an ideal insulation material for cables that operate in challenging environments or are exposed to extreme conditions.

How resistant neoprene cables are to environmental factors

Neoprene cables are renowned for its ability to operate efficiently across a broad temperature spectrum, making it adaptable to both hot and cold environments. Its inherent resistance to ozone and weathering ensures that cables sheathed in neoprene remain durable, even in challenging outdoor conditions.

Furthermore, neoprene’s chemical stability allows it to resist a variety of substances, including acids, alkalis, and organic solvents, positioning it as a preferred choice for industrial settings where cables may encounter such chemicals, such as in factories.

Additionally, most neoprene cables are flame-retardant and self-extinguishing, and often incorporate a supporting core to alleviate stress. For context, while neoprene cables can function in temperatures ranging from -25°C to 90°C, standard PVC-insulated cables typically have a threshold of up to 70°C.

Using polyvinyl chloride (PVC) cables outdoors

While polyvinyl chloride (PVC) is the standard insulation material in standard low-voltage wires, neoprene and ethylene propylene rubber (EPR) are better materials for cables that are installed in harsher environments. This is the case for reasons explained in the previous previous sections about the two materials.

PVC is susceptible to ultraviolet light oxidation and permanent heat deformation, and becomes brittle in cold temperatures. A PVC sheathed wire used outdoors directly exposed to the elements would quickly deform and fall apart, becoming faulty within a short period unless it is further shielded.

While exposed PVC cables installed outdoors are susceptibility to environmental factors, there are many scenarios where they can still be safely and effectively employed. In fixed installations, where the cables are shielded from direct exposure to the elements, PVC cables can be the preferred cable choice.

A common application in Singapore is the use of standard PVC four-core cables to connect an outdoor air conditioner condenser unit to the indoor aircon fancoil. These cables are typically housed within thick plastic trunking, which provides protection against UV exposure from sunlight, as well as rain and moisture.

However, the selection of the PVC cable is paramount. Opting for high-quality and appropriately sized PVC cables is crucial to ensure longevity and safety in such outdoor installations. Being a company with seasoned electricians and air conditioner technicians, we possess the expertise to select and install the appropriate cables.

How standard cables compare to neoprene cables

Basic electrical installations in Singapore use PVC insulated wires with a nominal area of 1.5mm² or 2.5mm². These cables are made of plain annealed copper, conforming to IEC60228 Class 2, and are insulated following the SS358-3 standards.

Electricians use these cables in light fittings, sockets, and typical residential and commercial electrical installations. Adhering to a standard cable colour code, these cables can be easily identified and installed within cable trays, conduits, cable trunking, or even concealed inside walls.

Neoprene cables are available with the same nominal conductor areas as standard wires. The main difference between the two cables are the different insulation materials and the presence of sheathing.

Using neoprene cables where PVC wires are normally used

While PVC cables do not match the mechanical robustness of neoprene or EPR cables, they are cost-effective, often being at least three times cheaper than neoprene cables. But their lack of mechanical robustness does not compromise their utility for indoor uses.

Installing neoprene cables in standard indoor environments would cost a lot more without much benefit in return. Moreover, from a practical standpoint, although neoprene cables are known to be easy to work with compared to alternatives designed for challenging environements, they are much more difficult to install compared to standard PVC cables.

Where and when we install neoprene cables

In the context of Singapore’s humid and tropical climate, the selection of the right cable is paramount. Neoprene cables, insulated with Ethylene Propylene Rubber (EPR), stand out as the preferred choice for outdoor electrical installations that are exposed to our weather conditions.

Given their weather-resistant properties, our electricians frequently use neoprene cables for installations in gardens, particularly for lighting and junction boxes. Additionally, they are the go-to for outdoor lighting setups and for running power to outdoor structures such as barbeque pits. The resilience of neoprene cables ensures not just functionality but also safety and longevity in these environments.